#C-Type injection molding machine

Explore tagged Tumblr posts

Text

Mastering the Silicone Overmolding Process: Techniques, Applications & Expert Support

Silicone overmolding is becoming a key process in many industries. From medical devices to consumer tech, this technique brings better durability, comfort, and style to products. As demand grows, mastering the process is crucial to ensure quality and efficiency. Understanding how to do it right can set your products apart and keep you ahead of the competition.

Understanding Silicone Overmolding: An Overview

What Is Silicone Overmolding?

Silicone overmolding is a manufacturing method where a layer of silicone is molded over an existing part. Unlike traditional molding, which shapes solid parts, overmolding adds a flexible silicone layer onto a substrate, like plastic or metal. This creates a stronger, more comfortable, and more functional product.

Overmolding has been around for decades, but technology has improved fast. Today, it allows brands to design products that feel better and last longer. It’s a way to integrate multiple functions and boost user experience.

Benefits of Silicone Overmolding

Choosing silicone overmolding offers many advantages:

Flexibility: Silicone stretches and bends without breaking, making it perfect for grips and seals.

High-temperature resistance: Silicone withstands extreme heat and cold.

Biocompatibility: Safe for medical and wearable products touching skin.

Enhanced product longevity: Adds extra protection and durability.

Ergonomic design: Improves handling and comfort.

Cost-effective in mass production: Once set up, it’s faster and cheaper to produce large quantities.

Common Industries Using Silicone Overmolding

Many industries rely on silicone overmolding because of its benefits:

Healthcare: Medical devices like catheters, prosthetics, and trainers.

Consumer Electronics: Smartphone cases, headphones, and fitness trackers.

Automotive: Dashboard parts, seals, and protective covers.

Techniques for Effective Silicone Overmolding

Material Selection and Compatibility

Picking the right silicone is key to success. Types like High-Temperature Vulcanizing (HTV) and Liquid Silicone Rubber (LSR) work best depending on the application. LSR is fast and suitable for high-volume runs, while HTV offers more durability.

Compatibility is just as important. Make sure your silicone bonds well with the substrate—whether plastic, metal, or other materials. Testing adhesion and durability beforehand saves headaches later.

Surface Preparation and Design

A clean surface is a must. Dirt, oil, or residue can cause poor bonding. Use suitable cleaning and priming methods to prepare the substrate.

Design tips include:

Draft angles: Simple changes that make removal easier.

Part shape: Keep geometries simple to avoid voids or weak spots.

Use inserts or molds to create complex shapes or add features like buttons or textures easily.

Overmolding Processes and Equipment

The main methods are:

Compression Molding: Good for low to medium volumes; simple but slower.

Transfer Molding: Better for small to medium batches; allows more complex parts.

Injection Molding: Ideal for high volume; precise and fast.

Modern machines come with automation and smart controls that improve quality. Adjust parameters like temperature, pressure, and cycle time to match your materials and design needs for best results.

Troubleshooting Common Challenges

Common problems include:

Delamination (layer separation): Usually caused by poor surface prep or incompatible materials.

Incomplete filling: Can happen if pressure or temperature are set improperly.

Mold wear: Use quality molds and maintain them regularly.

Expert tips include testing and adjusting process parameters often. For example, increasing mold temperature may improve flow and reduce air traps.

Applications of Silicone Overmolding: Case Studies & Industry Insights

Medical Devices: Ensuring Safety and Compliance

Silicone overmolding helps make medical devices safer and more comfortable. Catheters with soft silicone covers reduce irritation. These products must follow strict rules like FDA regulations and ISO standards, ensuring safety and reliability.

Consumer Electronics: Enhancing User Interaction and Durability

Overmolded grips make phones, headphones, and controllers more comfortable. They also protect sensitive electronics from shocks and drops. Many leading brands swear by silicone for quality feel and longevity.

Automotive and Industrial Uses

In cars, silicone overmolding is used for dashboard dials, seals, and protective covers. These parts must endure heat, moisture, and vibrations. Silicone’s durability makes it a smart choice to meet safety standards and environmental challenges.

New Trends and Future Opportunities

Innovations include using biocompatible and eco-friendly silicones. Smart silicones with embedded sensors or conductive features are emerging. These materials can connect products to the internet, opening new opportunities for innovation.

Expert Support and Collaborations in Silicone Overmolding

Choosing the Right Partner

Partner with molders who have experience in your industry. Look for certifications like ISO 13485 for medical or IATF16949 for automotive. Their proven quality ensures consistent results and compliance.

Collaborate for Custom Solutions

Work with experts to optimize designs and prototypes. Simulation tools can help test how materials will behave before manufacturing begins. This reduces waste and speeds up development.

Stay Updated on Industry Innovations

Attend trade shows, webinars, and training sessions. Engage with professional forums and industry groups to learn about new materials and processes. Staying current gives you a competitive edge.

Cost Optimization and Scale-Up Strategies

Transitioning from prototypes to mass production requires planning. Analyze your ROI, and don’t forget to use ongoing technical support to adjust processes and reduce costs over time.

Partnering with a Trusted Manufacturer

YEJIA, a leading custom silicone product manufacturer, provides expert silicone overmolding solutions tailored to client requirements. With years of experience and advanced molding capabilities, the company ensures precise, durable, and high-performance parts for various industries. From material selection and mold design to production and quality control, YEJIA offers full technical support to help customers achieve optimal product performance.

Common Substrate Materials

Silicone can be overmolded onto various materials including:

Plastics such as PC, ABS, PA, PPS, PEEK

Metals like stainless steel, aluminum, brass, and titanium

Other elastomers, depending on compatibility

Silicone Overmolding Techniques

Insert Molding: The substrate is inserted into the mold and silicone is injected around it. This is commonly used when the base part is pre-fabricated.

Two-Shot Molding: Both materials are molded in sequence in the same machine, providing stronger bonding and better process control.

Compression Overmolding: Less common but suitable for lower-volume production or specific geometries.

Conclusion

Mastering silicone overmolding takes understanding, experience, and good collaboration. Techniques like proper material selection, surface prep, and process control build a solid foundation for success. Working with industry experts ensures quality and saves time and money.

Keep learning, experimenting, and staying connected with innovations. Investing in proper training and choosing the right partners will help you produce top-quality, durable, and creative products. The future of silicone overmolding holds exciting possibilities—are you ready to lead the way?

#Compression Overmolding#Silicone Overmolding#silicone duckbill valve#liquid injection molding#silicone rubber valves

0 notes

Text

Explore High-Performance Ceramic Band Heaters from Excel Heaters

In many industries, machines need strong and reliable heat to run smoothly. Ceramic band heaters are one of the most popular choices for this job. They are used in machines that work with plastic, rubber, packaging, and other materials. If you need a heater that gives you high performance and energy savings, ceramic band heaters are a great option.

Excel Heaters is a trusted name when it comes to high-quality ceramic band heaters. Their products are designed to handle tough industrial tasks, run efficiently, and last a long time. In this blog, we will explore how ceramic band heaters work, where they are used, and why Excel Heaters stands out as a reliable supplier.

What Is a Ceramic Band Heater?

A ceramic band heater is a device that wraps around cylindrical parts of machines, like barrels, drums, or pipes. It heats these parts from the outside using electricity. Inside the heater, ceramic bricks cover a coil of wire that gets hot when power flows through it. The ceramic helps spread the heat evenly and reduces heat loss.

These heaters can reach high temperatures—up to 850°F (450°C) or more. They work well in places where strong and steady heat is needed for a long time.

Where Are Ceramic Band Heaters Used?

Ceramic band heaters are used in many industries, especially where heat is needed to melt or process materials. Some common uses include:

Plastic injection molding machines

Plastic extrusion machines

Blow molding equipment

Food processing units

Drum heating systems

Packaging machinery

They are ideal for machines that run for long hours and need consistent, high-temperature heating.

Benefits of Ceramic Band Heaters

Ceramic band heaters offer many benefits over other types of band heaters, such as mica heaters. Here are some key advantages:

1. High Heat Performance

Ceramic band heaters can handle higher temperatures than mica heaters. They also heat up faster and can maintain steady heat for long periods.

2. Energy Efficiency

The ceramic insulation reduces heat loss and keeps more heat inside. This helps save energy and lowers operating costs.

3. Even Heat Distribution

The ceramic core spreads the heat evenly over the machine surface. This prevents hot spots and ensures smooth production.

4. Long Life

Ceramic heaters last longer because they are made with strong materials and can handle tough working conditions.

Why Choose Excel Heaters?

When it comes to ceramic band heaters, Excel Heaters is a name you can trust. They have years of experience in making heating solutions for industrial use. Here’s what makes them a great choice:

1. Quality Materials

Excel Heaters uses high-grade stainless steel and ceramic components to build their heaters. These materials resist wear and tear and provide long-term performance.

2. Custom Sizes and Designs

Not all machines are the same. Excel Heaters offers custom-made ceramic band heaters to match your machine’s size and shape. Whether you need a small heater or a large one, they can build it for you.

3. Quick Heat-Up Time

Their heaters are designed to reach the desired temperature fast. This helps you save time and start production sooner.

4. Strong Insulation

Excel Heaters adds extra insulation to their products. This keeps the heat where it’s needed and reduces energy waste.

5. Easy Installation

Their heaters come with simple mounting options and clear wiring connections. This makes it easy for your team to install and replace them when needed.

6. Excellent Support

Excel Heaters provides full support before and after the sale. Their team helps you pick the right heater, answer your questions, and offer quick service when needed.

Choosing the Right Heater

Before buying a ceramic band heater, consider the following:

Machine size and diameter

Required temperature range

Voltage and wattage

Terminal type (how it connects to power)

Working environment (wet, dusty, high vibration)

If you’re not sure which heater to pick, the experts at Excel Heaters can help you find the best match.

Safety and Maintenance Tips

To get the best out of your ceramic band heater:

Install it tightly on the machine surface to improve heat transfer.

Avoid gaps or loose fittings, as they can cause heat loss.

Keep the terminal area clean and dry to avoid electrical problems.

Check the heater regularly for wear and replace it if needed.

A well-maintained heater performs better and lasts longer.

Conclusion

Ceramic band heaters are an important part of many industrial machines. They offer strong heating, energy savings, and long-lasting performance. Whether you work with plastics, packaging, or food processing, a high-quality ceramic heater can help your machine run better.

Excel Heaters provides reliable and efficient ceramic band heaters that meet industrial demands. With quality products, custom options, and great customer support, they make it easy to get the right heater for your equipment. If you're looking for performance and value, Excel Heaters is a smart choice.

0 notes

Text

Jerry Can Manufacturers in Bharuch: A Step-by-step Manufacturing Process

Whether you want to store/transport fuel or store chemicals and food, you need jerry cans. Jerry can manufacturers in Bharuch follow a step-by-step process to build durable and reliable containers. If you are curious on how this product is manufactured to ensure quality, safety and value, here is a peek into the behind-the-scenes action.

1. The first step indicates selecting the raw material to build the plastic drum. It is important to have the right plastic type for your needs. Most manufacturers tend to use high-density polyethylene (HPDE) as it offers a high strength-to-density ratio. Additionally, it provides chemical resistance and can be easily recycled. Moreover, you will notice it offers impact durability. This material is generally provided to the manufacturers in pellet or granule form. These white and translucent particles are mixed with colour pigments and UV stabilizers to create the material needed to build the plastic drums. The colour choices depend on what you aim to use the drum for. For instance, you use blue colour for water, yellow for diesel and green to manufacture drums that are useful to store chemicals.

2. The next process step followed by the jerry can manufacturers in Ankleshwar is known as extrusion blow molding. It is generally the core manufacturing method. In this technique, you create a hollow and seamless containers that come with a uniform wall thickness and structural integrity. There are several steps that are followed to achieve this drum type.

a. The first step is actual melting and extrusion, where the HPDE pellets are put into the hopper and after that into the heated extruder. This is the machine that comes with a rotating screw and moves your plastic across diverse heating zones. Once the plastic melts under the temperature, it converts into a thick and molten material. The manufacturer will then push this through a die head to produce a hollow plastic tube.

b. The jerry can manufacturers in Bharuch will then clamp this hollow plastic tube, also known as parison, between the two metal mold halves to shape it like a jerry can. The moment the mold is closed, a blow pin injects the compressed air into the tube, which will inflate the molten plastic. Eventually it will fill the cavity inside the mold.

c. The last step involves cooling and ejection, where the inflated mold is cooled using several channels. Once cooled, this would solidify into a jerry can and you can give it the desired shape. Once the mold opens, the jerry can is then put onto the conveyor for trimming it and giving it the finish.

3. The next step involves trimming the excess plastic, also known as flash, which is spread around the seams and handle of the drum. The manufacturer would use either automated or manual tools to complete the process. The trimmed plastic is then recycled into the manufacturing process to ensure sustainable outcomes and reduced material cost.

4. It is crucial for the jerry can manufacturers in Ankleshwar to carry out quality control and leak tests to ensure that the drums are proper. The leak test includes putting water or air through the drums to check for pinholes and cracks. The drop tests will determine the impact resistance of the drum. The last few steps involves actual handling, packaging and shipping of the drums.

0 notes

Text

Equipment Needs for a Startup Manufacturing Plant

Starting a manufacturing plant is an exciting yet challenging venture. One of the most critical aspects of setting up a successful operation is selecting the right equipment. The machinery you choose will impact production efficiency, product quality, and overall profitability.

In this blog, we’ll discuss the essential equipment needed for a startup manufacturing plant, factors to consider when selecting machinery, and tips to optimize your investment.

1. Understanding Your Manufacturing Requirements

Before purchasing any equipment, it’s crucial to define Machinery Solutions your production needs. Consider the following:

Type of Products: What are you manufacturing? (e.g., food, textiles, machinery, electronics)

Production Volume: Will you operate at small, medium, or large scale?

Automation Level: Do you need manual, semi-automated, or fully automated machines?

Budget Constraints: How much can you invest in machinery without compromising cash flow?

Once you have clarity on these factors, you can proceed with selecting the right equipment.

2. Essential Equipment for a Startup Manufacturing Plant

A. Production Machinery

The core of your manufacturing plant lies in the machines that transform raw materials into finished products. Depending on your industry, these may include:

CNC Machines – For precision cutting, drilling, and milling (metalworking, automotive parts).

Injection Molding Machines – For plastic product manufacturing.

3D Printers – For prototyping and small-batch production.

Assembly Line Robots – For automated assembly in electronics or automotive industries.

Packaging Machines – For sealing, labeling, and boxing products.

B. Material Handling Equipment

Efficient movement of raw materials and finished goods is vital. Key equipment includes:

Forklifts & Pallet Jacks – For transporting heavy materials.

Conveyor Belts – For smooth movement of products along the production line.

Cranes & Hoists – For lifting heavy machinery or materials.

C. Quality Control & Testing Equipment

Ensuring product quality is non-negotiable. Invest in:

Spectrometers & Calipers – For measuring dimensions and material composition.

Tensile Testers – To check material strength.

Vision Inspection Systems – For detecting defects in products.

D. Safety & Maintenance Tools

Worker safety and machine longevity should be a priority. Necessary tools include:

Fire Suppression Systems – Especially in chemical or welding plants.

PPE (Personal Protective Equipment) – Helmets, gloves, goggles, etc.

Lubrication Systems – To keep machines running smoothly.

E. Utilities & Support Systems

A manufacturing plant requires reliable infrastructure:

Power Generators – Backup in case of electricity failure.

Compressed Air Systems – For pneumatic tools.

HVAC Systems – To maintain optimal working conditions.

3. Factors to Consider When Choosing Equipment

A. Cost vs. Value

New vs. Used Equipment: New machines offer warranties and latest tech, while used ones are cost-effective but may require more maintenance.

Leasing vs. Buying: Leasing reduces upfront costs, but buying may be better for long-term savings.

B. Scalability

Can the equipment handle increased production in the future? Modular machines allow easy upgrades.

C. Energy Efficiency

Energy-efficient machines reduce operational costs. Look for certifications like ISO 50001.

D. Supplier Reputation & Support

Choose suppliers with good after-sales service, spare parts availability, and training programs.

E. Compliance & Standards

Ensure machinery meets industry regulations (e.g., OSHA, ISO, CE Marking).

4. Tips for Optimizing Equipment Investment

A. Start with Essential Machines First

Avoid overspending on advanced equipment if basic models suffice for initial production.

B. Implement Preventive Maintenance

Regular servicing extends machine life and prevents costly breakdowns.

C. Train Employees Properly

Skilled operators maximize efficiency and reduce machine misuse.

D. Automate Where Possible

Automation improves precision and reduces labor costs in the long run.

E. Monitor Performance with IoT & AI

Smart sensors can track machine health and predict failures before they happen.

5. Common Mistakes to Avoid

Overestimating Production Needs → Leads to underutilized machinery.

Ignoring Future Expansion → Results in costly replacements later.

Neglecting Safety Standards → Increases workplace accidents.

Choosing Cheap, Low-Quality Machines → Frequent breakdowns hurt productivity.

Conclusion

Selecting the right equipment for your startup manufacturing plant is a make-or-break decision. By assessing your production needs, prioritizing essential machinery, and considering factors like cost, scalability, and efficiency, you can build a strong foundation for your business.

Invest wisely, maintain your equipment diligently, and stay updated with industry advancements to ensure long-term success.

0 notes

Text

How Does Melt Flow Index Tester Works

Source of Info: https://www.goglides.dev/saniya/how-does-melt-flow-index-tester-works-3f77

Introduction

In the plastics production and quality control industries, the Melt Flow Index Tester (MFI Tester) is an important equipment. The Melt Flow Index (MFI) of polymer materials can be measured by giving important information on their density, processability and general quality. Manufacturers, researchers and engineers that need to guarantee accuracy and conformation to industry standards need to understand how an MFI Tester functions. The parts, testing process, factors affecting it and uses of this equipment are all fully explained in this article.

What Is Melt Flow Index (MFI)?

The rate at which a polymer material flows through a standard die at a given load and temperature can be measured by the Melt Flow Index Tester. Grams per 10 minutes (g/10 min) is the unit of measurement. While a lower MFI indicates higher viscosity and increased flow resistance, a higher MFI indicates lower viscosity and easier processing capabilities. It is important to understand MFI since it has a direct impact on processing speed and product quality. Manufacturers can use it to measure polymer usefulness for blow molding and injection molding. The test ensures that materials fulfill needed standards and offers a fast, compatible method of comparing batches of polymers.

Components of a Melt Flow Index Tester

The following are all necessary parts of a Melt Flow Index Tester: Heated Barrel: Maintains the same temperature for melting the material and creates an accurate setting for testing. Die (Orifice): A standard sized injector through which molten polymer passes, making sure accurate and consistent ejection. Piston and Load Weights: Apply pressure for pushing the molten polymer through the die, matching real world manufacturing conditions. Temperature Controller: Ensures correct temperature control throughout testing, maintaining similarities between material batches. Cutting Mechanism: To maintain accuracy, some testers use an automated device that cuts the injected polymer at specified times. Timer: Tracks the test duration in order to find the MFI. Balance/Scale: Measures the weight of the ejected plastic to properly calculate the flow rate.

What Is the Workflow of a Melt Flow Index Test?

The Melt Flow Index Tester uses methods that meet ASTM D1238 and ISO 1133 testing requirements. Here a step-by-step working procedure:

Preheating the Machine

Before starting the test the instrument gets preheated to the right temperature (usually between 190°C and 300°C depending on the polymer type). This guarantees that the barrel gets the right temperature before the material is added by reducing variations.

Loading the Polymer Sample

A carefully measured sample of polymer grains or powder is inserted in the heated barrel of the tester. The sample needs to be processed carefully to safeguard consistency and avoid pollutants which might impact the results of the test.

Melting the Polymer

Once inside the barrel the polymer melts at the specified temperature. The Melt Flow Index Tester makes sure of a uniform temperature that allows the polymer to reach its full molten condition before the test begins. This step's duration changes depending on the polymer type and testing needs.

Applying Load to the Polymer

After the polymer has properly melted, an average load (ranging from 2.16 kg to 21.6 kg, depending on the material being tested) is applied to the piston. The applied force moves the molten polymer through the die at the same pace, based on real world production situations.

Extrusion Through the Die

As pressure is applied, the molten polymer expands through the normal size die. The flow rate is affected by the polymer's thickness and molecular weight. The die's sizes are important in creating a controlled and accurate flow.

Collecting and Measuring the Extrudate

The stretched polymer is cut at regular intervals (usually every 10 minutes), by hand or by a computerized process. To achieve exact measurements the sliced samples are weighed on an exact balance.

Factors Affecting Melt Flow Index Testing

Many factors affect the accuracy of MFI measurements which including: Temperature Variations: Even little changes can affect polymer flow rate of polymer which provides different results. Load Weight: Different materials require different loads to achieve accurate test results. Polymer Composition: Compounds, fillers and molecular weight distribution have an important effect on flow behavior. Operator Handling: Reliable results require proper sample loading, accurate cutting and careful measurement of weight. Barrel Cleanliness: Previous tests' remaining particles can mix with new samples, reducing the accuracy of results.

Applications of Melt Flow Index Testing

The Melt Flow Index Tester is commonly used in the following industries:

Plastic Manufacturing

Maintains raw material equality. Helps in selecting right supplies for extrusion, blow molding and injection molding.

Quality Control & Compliance

Monitors the quality of products all over production lines. Verifies with product standards with international standards to ensure reliable performance.

Research & Development

Helps in creating new polymer mixtures with specified flow properties. Helps with analyzing the impact of chemicals, fillers and processing conditions on polymer behavior.

Recycling Industry

Calculates the capacity for processing of returned plastics. Helps with testing the possibility of recyclable plastic resources for the production of new products.

Advantages of Using a Melt Flow Index Tester

Using a Melt Flow Index Tester has different advantages:

Accurate and Repeatable Measurements:Makes sure the same thickness in polymer analysis. Quick Analysis: Provides quick results for making decisions in manufacturing settings. Cost-Effective: When compared to different methods of measuring its thickness, it saves time and resources. Standardized Testing: According to global industry standards for polymer testing, maintaining continuity between multiple testing facilities as well as production areas. Predictability in Processing: Helps manufacturers in understanding how a polymer would react in practical situations.

Limitations of Melt Flow Index Testing

The MFI Tester is a useful tool, however it has specific limitations: Limited Molecular Structure Analysis: Does not provide details on polymer molecular weight distribution or twisting. Not Suitable for Highly Viscous Polymers: Different rheological testing techniques could be needed for some high density materials. Influence of Additives: Flow rate can be impacted by specific stabilizers, polymers and fillers which may result in different outcomes. Single-Point Measurement: Different temperatures and pressures can be found in everyday situations, while the MFI test only offers data for one set of parameters.

Conclusion

By offering a simple and dependable way to check the flow properties of polymers, the Melt Flow Index Tester is important for polymer testing. Manufacturers and researchers can maintain material reliability, optimize the processes they use and follow the industry standards by understanding how it functions.

Frequent MFI testing guarantees that polymers meet the required standards, improving product quality and manufacturing profitability. The Melt Flow Index Tester continues to be an important instrument in the polymer industry, supporting its production of high-quality plastic products globally, whether in quality control, research or recycling.

0 notes

Text

Small-Scale Plastic Recycling: Innovative Solutions for Individuals and Communities

Plastic pollution is one of the most pressing environmental issues of our time. With over 300 million tons of plastic produced annually worldwide, much of it ends up in landfills, oceans, and other natural environments, causing significant harm to ecosystems and human health. Large-scale industrial recycling plays a crucial role in managing plastic waste, but small-scale plastic recycling can also offer powerful, community-driven solutions to this global problem.

Small-scale plastic recycling is essential for communities, businesses, and individuals looking to make a meaningful impact on reducing plastic waste. Whether it’s reducing your own waste footprint, supporting local businesses, or creating innovative products from recycled materials, small-scale recycling offers numerous opportunities for people to participate in the circular economy. In this blog, we will explore some of the best solutions for small-scale plastic recycling, how these methods work, and how they can be implemented in everyday life.

1. Home-Based Recycling Solutions

Home-based plastic recycling is an accessible way for individuals to reduce plastic waste and contribute to recycling efforts directly from their homes. While traditional recycling programs managed by municipalities may not recycle all types of plastics, home-based systems give people the ability to recycle different kinds of plastics, like bottle caps, bags, and packaging, that often aren't accepted in curbside programs.

a. Manual Sorting and Cleaning

Before any plastic can be recycled at home, it must be sorted and cleaned. Sorting plastic by type (e.g., PET, HDPE, PP, etc.) is crucial since different types of plastics require different processing methods. Washing the plastic is also essential to remove any food residue or contaminants that could interfere with the recycling process. While this method is labor-intensive, it is a fundamental step in any recycling process.

b. Shredding Plastic at Home

Shredding plastic is a critical step in home recycling. Small, affordable plastic shredders are available in the market that allow you to break plastic items into smaller, more manageable pieces. Shredded plastic is easier to melt or mold into new products. Shredding machines for home use vary in size and price, making it a viable option for households looking to reduce their plastic waste footprint.

c. Melting and Repurposing Plastic

Once plastic is shredded, it can be melted down and repurposed into new items. Small-scale plastic extruders and injection molding machines are available for home use, allowing individuals to melt shredded plastic and turn it into new products such as containers, tools, and household items. Some systems are specifically designed to work with DIY molds, making it easier to create custom products.

2. Community-Based Recycling Initiatives

While individual efforts are essential, collective action in the form of community-based recycling can have an even broader impact. Community recycling initiatives bring people together to work towards reducing plastic waste on a local level. These initiatives often involve education, workshops, and shared recycling equipment to allow for more efficient processing.

a. Precious Plastic: A Global Movement

One of the most well-known community-based small-scale recycling projects is Precious Plastic, a global initiative that empowers individuals and communities to start their own small-scale recycling workshops. Precious Plastic offers open-source blueprints for building plastic recycling machines, including shredders, extrusion machines, and injection molders, which can be built using locally available materials.

Precious Plastic workshops can be set up in community centers, schools, or even garages, allowing people to recycle plastic waste into new products such as furniture, building materials, and decorative items. The initiative encourages the creation of local businesses based on recycling, providing economic opportunities while promoting sustainability.

b. Collection Hubs and Drop-Off Points

Another effective community-based solution is setting up plastic collection hubs where individuals can drop off their plastic waste for recycling. These hubs can be located at community centers, schools, or local businesses. Once the plastic is collected, it can be sorted and sent to local recycling facilities or processed at community workshops using shredders and extruders.

c. Recycling Co-ops

Recycling co-ops are organizations where members pool resources to set up small-scale recycling operations. These co-ops can invest in shared equipment, such as shredders and extruders, which members use to process plastic waste. The co-op can then sell the recycled plastic or products made from it, with profits reinvested into the co-op to support further recycling efforts.

3. Plastic Recycling for Small Businesses

Small businesses can play a crucial role in reducing plastic waste by integrating recycling into their operations. There are several ways that small-scale plastic recycling can benefit businesses, from reducing waste management costs to creating new revenue streams through the sale of recycled plastic products.

a. In-House Recycling Systems

Small-scale plastic recycling systems, such as shredders and extruders, can be integrated directly into business operations. For example, businesses that generate a lot of plastic waste, such as packaging or plastic bottles, can set up an in-house recycling system to process that waste into reusable materials. These recycled materials can then be used to manufacture new products, reducing the need for virgin plastics and cutting down on waste disposal costs.

b. Creating Recycled Plastic Products

Many small businesses are using recycled plastic to create innovative products. For instance, companies are producing everything from eco-friendly furniture to fashion accessories using recycled plastic. Businesses can take advantage of small-scale recycling machinery to turn plastic waste into raw material for new products, allowing them to reduce their environmental impact while tapping into the growing demand for sustainable products.

c. Partnerships with Local Recycling Workshops

Small businesses that may not have the resources to set up their own recycling systems can partner with local recycling workshops, such as Precious Plastic workspaces, to handle their plastic waste. This can be a mutually beneficial relationship, as businesses can reduce their waste management costs while supporting local recycling initiatives, and workshops gain access to more plastic material to process.

4. Innovative Technologies for Small-Scale Plastic Recycling

Technology is playing an increasingly important role in small-scale plastic recycling, with innovative solutions emerging that make it easier, more efficient, and more accessible to individuals and communities.

a. Desktop Recycling Machines

Desktop plastic recycling machines, such as the ProtoCycler, are compact systems designed for home or office use. These machines can shred, melt, and extrude plastic, turning it into filament for 3D printers. The ability to recycle plastic waste into 3D printing filament opens up opportunities for individuals, hobbyists, and small businesses to create custom products, prototypes, or tools from their plastic waste.

b. Plastic-to-Fuel Systems

Another emerging technology in small-scale plastic recycling is plastic-to-fuel systems. These systems use pyrolysis to break down plastic waste into liquid fuel, which can then be used as an energy source. While these systems are still in the early stages of development, they hold promise as a way for individuals and communities to reduce plastic waste while producing renewable energy.

c. Micro Recycling Factories

Micro recycling factories, like those pioneered by researchers at the University of New South Wales in Australia, aim to turn plastic waste into valuable materials using small, portable systems. These modular, scalable recycling systems can be deployed in local communities or even remote areas to recycle plastic waste into usable raw materials like plastic filaments, pellets, or other industrial inputs.

5. Education and Awareness Initiatives

Education and awareness are vital components of small-scale recycling efforts. Many people are still unsure of how to recycle plastic correctly or are unaware of the possibilities for small-scale recycling. Educational initiatives, workshops, and outreach programs can help empower individuals and communities to take action.

a. Workshops and Training Programs

Hosting workshops on small-scale recycling methods can teach people how to sort, clean, and recycle plastic effectively. These workshops can include hands-on demonstrations of shredding, melting, and repurposing plastic into new products. Training programs can also teach individuals how to build and operate small-scale recycling machines, such as those designed by Precious Plastic.

b. Awareness Campaigns

Local governments, businesses, and community organizations can launch awareness campaigns to encourage more people to get involved in plastic recycling. These campaigns can provide practical tips on reducing plastic waste, information on local recycling options, and details on how individuals can start their own small-scale recycling projects.

Conclusion

Small-scale plastic recycling offers a range of solutions for individuals, businesses, and communities to reduce plastic waste and promote sustainability. From home-based recycling systems and community workshops to innovative technologies and educational programs, there are many ways to get involved in the circular economy and make a positive impact on the environment.

As the world continues to grapple with the challenge of plastic pollution, small-scale recycling represents a powerful tool for reducing waste, conserving resources, and fostering a culture of sustainability. By embracing these solutions, we can all contribute to a cleaner, greener future.

0 notes

Text

Die Casting - An Insight into the Intricate Metal Forming Process

Die casting is a metal forming process where molten metal is injected at high pressure into steel molds or dies. Due to the high pressures involved, it results in products with very tight tolerances and precise dimensional specifications. This helps produce intricate components with complex internal passages in high volumes, at competitive costs compared to other manufacturing processes. History and Applications It is a relatively old manufacturing technology that was first developed in the late 18th century for producing metal buttons and thimbles. Over the years, advancements in metal alloys and casting equipment led to expanding applications of it, especially for zinc and aluminum. Today, commonly die cast metals include aluminum, zinc, magnesium, copper and tin-based alloys. Major industries using die cast components include automotive, industrial equipment, electronics, hardware, and household appliances. Common applications are engine parts, transmission components, housings, casings, and covers for electronics, tools, and consumer goods. It accounts for over 60% of all aluminum cast parts produced globally. Different Methods There are two main casting methods in use today - hot chamber and cold chamber Die Casting . Hot chamber machines maintain molten metal at a high temperature inside a holding furnace. Cold chamber machines solidify molten metal in a shot sleeve before injecting it into the die under pressure. Within these, there are further variants depending on the type of filling method - gravity, low/high pressure, and squeeze casting. Hot chamber casting is preferred for zinc and tin-based alloys, while aluminum alloys are commonly cold chamber die cast. Each method has merits suited for certain alloy compositions and part sizes/thicknesses. Process Steps The key steps involved in casting are: 1. Preparation of die and mold cavity 2. Melting and alloying of metal 3. Metal conditioning and transfer 4. Shot delivery into the die cavity 5. solidification under applied pressure and cooling 6. Die opening and part ejection 7. Finishing of cast parts The die or mold containing the cavity of desired part shape is first prepared using tool steels. Molten metal at 700-800°C is transferred and conditioned in the shot sleeve of the Die Casting machine. On trigger, a shot of melt is injected rapidly into the die cavity under very high pressures of 600-1500 kg/sq cm before solidifying. Accurate temperature control is vital to obtain quality castings. Design Considerations for Die Cast Parts Designing die cast parts requires careful planning to ensure production feasibility, dimensional accuracy, and assembly/performance needs. Key factors considered are part size/weight limitations, wall thickness variations and thick/thin sections, draft angles, gates and risers placement, machining/finishing requirements post casting, functional lives under service loads/temperatures, and surface finish needs. Finite element analysis involving thermo-mechanical simulations is often used at the design stage to validate castability. Functional designs help achieve dimensional consistency and elimination of defects in high volume production. Get more insights on Die Casting

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#Die Casting#Metal Casting#Precision Manufacturing#Aluminum Casting#Zinc Casting#Casting Process#Industrial Casting#Mold Casting

0 notes

Text

The Marvels of Reaction Bonded Silicon Carbide: A Comprehensive Overview

In the realm of advanced ceramics, Reaction Bonded Silicon Carbide (RBSC) stands out as a material of remarkable strength, durability, and versatility. This high-performance ceramic has found applications across a wide array of industries, from aerospace and defense to electronics and energy. This article delves deep into the properties, manufacturing process, applications, and benefits of RBSC, showcasing why it is a material of choice for many demanding applications.

What is Reaction Bonded Silicon Carbide?

Reaction Bonded Silicon Carbide is a type of silicon carbide ceramic that is known for its superior mechanical properties and high resistance to wear, oxidation, and corrosion. Unlike other forms of silicon carbide, RBSC is produced through a unique reaction bonding process that imparts exceptional properties to the final product.

Manufacturing Process of RBSC

The production of Reaction Bonded Silicon Carbide involves several meticulous steps:

Mixing and Shaping:

The process begins with a mixture of silicon carbide (SiC) powder and carbon (C) materials. These materials are thoroughly blended to ensure uniformity.

The mixture is then shaped into the desired form using various techniques such as pressing, extrusion, or injection molding.

Green Machining:

Once the material is shaped, it undergoes green machining to refine its dimensions and surface finish. This stage allows for precision adjustments before the reaction bonding process.

Reaction Bonding:

The shaped and machined green body is placed in a high-temperature furnace under a controlled atmosphere.

In the furnace, the silicon carbide reacts with the carbon to form silicon carbide bonds, resulting in a dense, hardened structure. This reaction typically occurs at temperatures between 1,400°C and 2,200°C.

Final Machining:

After the reaction bonding, the ceramic part undergoes final machining to achieve the exact specifications required. This step is crucial for applications demanding tight tolerances and precise geometries.

Properties of Reaction Bonded Silicon Carbide

RBSC exhibits a unique combination of properties that make it suitable for high-performance applications:

High Hardness:

RBSC is incredibly hard, ranking just below diamond on the Mohs scale. This makes it highly resistant to wear and abrasion.

Exceptional Strength:

The material boasts excellent mechanical strength, allowing it to withstand high-stress environments without deforming or breaking.

Thermal Stability:

RBSC maintains its properties at elevated temperatures, making it ideal for high-temperature applications.

Chemical Resistance:

The material is highly resistant to chemical attack, including acids, alkalis, and oxidative environments.

Low Density:

Despite its strength, RBSC is relatively lightweight, which is advantageous in applications where weight reduction is critical.

Applications of Reaction Bonded Silicon Carbide

Thanks to its outstanding properties, RBSC is employed in a wide range of industries and applications:

Aerospace and Defense:

RBSC is used in the manufacturing of components such as missile nozzles, heat shields, and armor due to its high strength and thermal stability.

Industrial Machinery:

The material is ideal for wear-resistant components like pump seals, bearings, and valve parts, where durability and reliability are essential.

Electronics:

RBSC is utilized in semiconductor processing equipment, where its chemical resistance and thermal stability are crucial.

Energy:

In the energy sector, RBSC is used in applications such as gas turbine components and heat exchanger tubes, which require high thermal conductivity and resistance to harsh environments.

Automotive:

The automotive industry employs RBSC in applications like brake discs and engine components due to its wear resistance and thermal properties.

Chemical Processing:

RBSC is used in chemical processing equipment, including reactors and pipelines, thanks to its resistance to corrosion and chemical attack.

Advantages of Reaction Bonded Silicon Carbide

The unique properties of RBSC offer several advantages over other materials:

Longevity:

The wear and corrosion resistance of RBSC ensure a longer lifespan for components, reducing maintenance and replacement costs.

Efficiency:

The material’s thermal conductivity and stability enhance the efficiency of thermal management systems, improving overall performance.

Cost-Effectiveness:

While the initial cost of RBSC components may be higher, their durability and reduced need for maintenance make them cost-effective in the long run.

Versatility:

RBSC’s ability to perform under extreme conditions makes it versatile for a variety of demanding applications across multiple industries.

Challenges and Considerations

Despite its many advantages, there are some challenges associated with the use of RBSC:

Manufacturing Complexity:

The production process of RBSC is complex and requires precise control over temperature and atmosphere, making it more challenging than other ceramics.

Cost:

The initial cost of RBSC components can be higher compared to other materials, which may be a consideration for some applications.

Machining Difficulty:

The hardness of RBSC makes it difficult to machine, requiring specialized equipment and expertise.

Conclusion

Reaction Bonded Silicon Carbide is a remarkable material that offers a unique combination of strength, durability, and resistance to extreme conditions. Its superior properties make it an ideal choice for a wide range of high-performance applications across various industries. As technology continues to advance, the demand for materials like RBSC is expected to grow, driving further innovation and development in this field. Whether in aerospace, industrial machinery, or electronics, RBSC stands out as a material that delivers exceptional performance and reliability.

0 notes

Text

Application of Acrylic Material in Thermoforming

With the demand for diversified designs and the wide application of new materials, plastic materials are favored by designers and users because of their unique characteristics. There are many types of plastic materials, with obvious characteristics and wide applications, acrylic materials are undoubtedly the ones.

Ⅰ. Thermoforming

With the continuous development of science and technology, the manufacturing industry is also constantly innovating and progressing. Among them, thermoforming process, as an emerging manufacturing technology, is gradually becoming a new trend in the future manufacturing industry.

Thermoforming is divided into thin gauge thermoforming and heavy gauge thermoforming according to the thickness of the sheets.

Thermoforming is a plastic processing technology. The main principle is to heat a flat hard plastic sheet to soften it, then use vacuum to adsorb it to the surface of the mold, and then cool it into shape. It is widely used in plastic packaging, lighting, advertising, decoration and other industries.

Heavy gauge thermoforming refers to the use of materials with a thickness exceeding 2mm, which cannot be vacuum formed on fully automatic tools. A semi-automatic vacuum forming machine dedicated to thick gauge thermoforming must be used for processing and production.

To optimize the sheet forming process, it is crucial to consider various factors. Begin by carefully managing stress concentration heat sheet, ensuring that ambient air temperature is controlled. Achieve uniform temperature distribution across the sheet, paying particular attention to the sheet interior's cooling time. Use a proper mold covering to maintain forming temperature low. Employ a blowing mold consists of optical light sensors for precise monitoring. Alternatively, a jig or soft material can be utilized to enhance the cooling process. Implementing a horizontal heating system further contributes to the overall efficiency and effectiveness of the sheet forming operation.

Vacuum forming can be used for product design and manufacturing of rear-projection TV back covers, displays, medical equipment, textile machinery, automotive accessories, and product design and manufacturing in precision electronics, medical equipment, and cosmetics industries.

The main advantage of pressure forming is that it can produce complex shapes and sizes, while also providing supporting services during the manufacturing process, such as printing and assembly, to meet vacuum forming requires of different customers.

Ⅱ. Acrylic Sheet

Acrylic

Acrylic (PMMA) particles are colorless or transparent material with a specific gravity of 1.19 g/cm3 and low surface hardness. They are easily scratched by hard objects and difficult to catch fire. The melting point of PMMA is about 130–140°C, which is much lower than the high temperature of glass, which is about 1000 degrees.

The panel is coated with a high concentration of ultraviolet absorber. Acrylic has high transparency, can be weathered for a long time, never fade, has a service life of 5 to 8 years, and has good light transmittance, up to 93%, with excellent light transmittance and light soft.

Acrylic sheet is a plexiglass processed through a special process. It has strong hardness, good material, radiation protection, and good light absorption effect. With the development and widespread application of optical technology, it has gradually been widely used in industrial manufacturing and modern home life. middle. Moreover, acrylic materials have large sales volume and high recognition in the market.

PMMA has the advantages of being light, cheap, and easy to form. Its forming methods include casting, injection molding, machining, vacuum forming, etc. Injection molding, in particular, can be produced in large quantities with simple process and low cost. Therefore, its application is becoming more and more widespread, and it is widely used in instrument parts, automobile lights, optical lenses, transparent pipes, etc.

Why is Acrylic Sheet Suitable for Thermoforming?

Appearance

From the appearance point of view, acrylic sheets have the same transparency as crystal, with good light transmission effect, which can reach more than 93%. In the design and manufacturing process, many different colors can be customized according to requirements.

The dye effect is good. After a long period of There is no possibility of color fading after use. Only with good quality can it be widely promoted and used in the decoration process.

Good Processing Performance

It has excellent heat resistance. Generally speaking, the surface of its acrylic sheet has the advantage of very good resistance to high temperatures after encountering high temperatures. Of course, for different size ranges, they all need to be processed before they can be installed.

Its processing performance is relatively strong, and the quality and performance are the same as before processing. At the same time, it has good toughness and no defects will appear during the processing, the outdoor service life is about 5-10 years, and the color remains as new during use.

Production Process

In terms of the production process of acrylic sheets, there are mainly two types: casting type and extrusion type. The hardness and toughness of the sheet are improved through hot processing technology. This is why at the current stage, acrylic panels installed outdoors will not have any quality problems after a long period of weathering.

Therefore, the emergence of this new sheet material can have unique technical advantages from this process and form its own characteristics at the current stage.

Cast Plate: Higher molecular weight, excellent stiffness, strength and excellent chemical resistance. Therefore, it is more suitable for processing large-sized sign plaques, and the softening process takes a relatively long time.

This sheet is characterized by small batch processing, unmatched flexibility in color system and surface texture effects by other products, and complete product specifications, suitable for different needs.

Extruded plate: Compared with cast plate, extruded plate has lower molecular weight and weaker mechanical properties, but has higher flexibility, which is beneficial to bending and thermoforming processing, and its softening time is shorter. When processing larger-sized sheets, it is beneficial to various rapid vacuum forming.

At the same time, the thickness tolerance of extruded plates is smaller than that of cast plates. Since extruded boards are produced automatically in large batches, the colors and specifications are difficult to adjust, so the diversity of product specifications is subject to certain restrictions.

Translucency

In terms of appearance light transmission effect, there are mainly types such as transparent, translucent, milky white, etc. The colors are different, and the surface effects will also be different, and the visual impact is very strong.

Excellent Material

Acrylic sheet is a new green and environmentally friendly material in the 21st century. It has a high recycling rate and can be reused to make simple sheets. It has strong light transmittance. These characteristics make it play a key role in the decoration process.

Ⅲ. Application of Acrylic Thermoforming Products

In terms of engraving, decoration, handicraft production, advertising signs, light boxes, etc. PMMA has the advantages of being light, cheap, and easy to form.

Therefore, its application is becoming more and more widespread, and it is widely used in instrument parts, automobile lights, optical lenses, transparent pipes, etc.

In construction, it is mainly used in lighting bodies, roofs, sheds, stairs and interior wall panels. The application of acrylic in lighting lampshades and automotive lamps on highways and high-end roads is also quite rapid.

With the construction of hotels, guesthouses and high-end residences in big cities, lighting bodies have developed rapidly. Lighting bodies made of extruded plexiglass panels have the characteristics of high overall structural strength, light weight, high light transmittance and good safety performance. Compared with inorganic glass lighting devices, it has great advantages.

In terms of sanitary ware, acrylic can be used to make bathtubs, washbasins, dressing tables and other products. Acrylic bathtubs have been widely used due to their luxurious appearance, depth, easy cleaning, high strength, light weight and comfortable use.

Acrylic is the best new material for manufacturing sanitary ware after ceramics. Compared with traditional ceramic materials, in addition to its unparalleled high brightness, acrylic also has the following advantages:

It has good toughness and is not easy to be damaged, it has strong repairability. Just use soft foam and a little toothpaste to wipe the sanitary ware as new.

The texture is soft and does not feel cold and biting in winter.

The colors are bright and can meet the individual pursuits of different tastes.

Using acrylic to make basins, bathtubs, and toilets is not only exquisite in style and durable, but also environmentally friendly. Its radiation is almost the same as the radiation of the human body's own bones.

Acrylic can be made into various fashionable products, such as leather bags, waist chains, watches, high heels, heels, hair accessories, brooches, bracelets, buttons, earrings, necklaces, rings, pendants, photo frames, etc. There are many types and unlimited development space for continuation.

At the same time, acrylic material has high processing plasticity and good surface hardness and transparent luster. It is often used by designers to match with various materials in the design of various exquisite containers to add texture and practicality to the containers, such as lipsticks and Delicate containers such as chemicals, and other daily necessities such as massagers, jewelry boxes, fans, etc.

Taking advantage of the cool feeling of acrylic material and combining it with creative design, acrylic material is perfectly presented in a variety of popular boutiques.

Acrylic thermoformed door panel series: European style, Chinese style doors, door frames, dado panels, ceilings, gussets, etc.

Acrylic thermoformed curtain boxes, window sill panels, window covers, etc.

Acrylic thermoformed furniture series: desktops, benches, countertops, shelves, kitchens (bookcases, wardrobes), etc.

Acrylic thermoformed series production of various speakers.

Processing and production of acrylic thermoformed vehicles and special-shaped decorative products for boats.

Ⅳ. Advantages of Thermoformed Acrylic Products

Transparency

Colorless and transparent organic glass sheet with a light transmittance of over 92%.

Excellent Weather Resistance

It has strong adaptability to the natural environment. Even if it is exposed to sunlight, wind and rain for a long time, its performance will not change. It has good anti-aging performance and can be used outdoors with confidence.

Good Processing Performance

Suitable for both machining and vacuum forming, acrylic panels can be dyed, and the surface can be painted, screen-printed or vacuum coated.

Excellent Comprehensive Performance

Acrylic boards come in a wide variety of colors, and have extremely excellent comprehensive properties, providing designers with a variety of choices. Acrylic boards can be dyed, and the surface can be spray-painted, screen-printed or vacuum coated.

Non-toxic

It is harmless even if it comes into contact with people for a long time, and the gas generated when burned does not produce toxic gas.

Made of PMMA acrylic thermoforming, it has the characteristics of good light transmittance, bright and clean exterior and interior, environmental protection, and can be painted. The color can be changed to produce products of different specifications and shapes according to customer requirements.

Mainly used in plastic transparent covers of game consoles, lampshades, observation instrument covers, leisure furniture hammocks, organic handicrafts, bank signboards, advertising light boxes, etc.

Ⅴ. Precautions for Acrylic Thermoforming Production

General acrylic will undergo thermal deformation at about 100 degrees Celsius, so you must pay attention to this temperature when using it, and if it is to be used continuously, the temperature cannot be higher than 90 degrees.

When acrylic thermoformed products become blurry or unclean due to slight scratches or dust adsorption due to static electricity, you can use 1% soapy water to wipe them clean with a soft rag.

The hardness of the thermoformed surface is comparable to that of aluminum, so care should be taken to avoid scratching the surface when using or processing acrylic. If it is accidentally scratched, it will need to be restored by polishing.

When installing acrylic products, thermal expansion and contraction must be taken into consideration, and there must be a space for expansion and contraction during assembly.

If the preliminary processing work is not done well, the acrylic thermoformed product will also be deformed at the moment of demoulding, and the quality of the deformed product will inevitably be affected. In order to avoid similar problems from happening again, we must develop corresponding solutions to this problem.

In order to prevent deformation after pressure forming is demolded, the operator is first required to check the temperature of the cooling water, and at the same time adjust the water volume of the nozzle to meet the specified range. Secondly, the wind direction at each location must be adjusted to find the most suitable forming pressure for acrylic thermoforming production.

In addition, when demoulding, try to use the pressure of vibrating the upper mold to force smooth demoulding. If the air volume at the bottom can be appropriately increased, it will also be helpful to ensure the quality of acrylic thermoformed products. If these cannot solve the problem, the only way to overcome the deformation problem is to re-make the upper mold.

Conclusion

With the continuous advancement of social science and technology and the continuous improvement of process technology, acrylic thermoforming will have broader market prospects and application prospects in the future. Its future development trends include the following aspects:

1. Continuous improvement of creativity: As people pay more and more attention to personalization, acrylic thermoforming will use more creativity to create more unique products through different processes and materials.

2. More environmentally friendly and energy-saving: When making acrylic thermoforming products, low-carbon, environmentally friendly, and energy-saving methods will be increasingly used to achieve a greener production environment.

3. Upgrading of materials: As people pay more and more attention to health and environmental protection, acrylic blister materials will increasingly use healthy, environmentally friendly and safe materials, and improve the performance indicators of the materials through technical means.

0 notes

Text

What is the bus machine (what is the cost of Guangdong CNC bus punching machine)?

The winding mold is an important part of the parent wire winding and processing coil. The type and size of the coil forming are determined by the mold. There are many mold types used in the parent line machine. According to the different types of industry applications and coil types, the mold has different materials. , Different structures, let's briefly introduce the application of common transformer winding molds, motor winding molds, and skeleton winding molds.

When cleaning the old bus motor or an imported motor to the heart spherical bearing, the rolling beads, a bears, and the inner ring should be transferred horizontally from the outer ring before immersing the hot oil. Should not exceed 20 ° C. What does the bus machine do?

Generally speaking, electrical products are a winding coil made of lacquer copper threads. Generally, the textile industry is a yarn for various winding lines such as artificial fiber wires in the cotton yarn industry. These all require the parent machine machine to go around.

Remove the outer shell of the y -axis, manually unscrew the two screws on the side of the pallet, expand the bracket, pull the mold frame down the outer part, replace the required molds (including the upper and lower molds). When the mold must be tightened, then push the mold back, turn off the bracket, tighten the two screws on the side of the supporting rack, and the upper and lower mouths of the mold must be consistent when replacing the long mouth mold.

What is the busbar machine is mainly suitable for high and low voltage switching cabinets and transformer manufacturing industries. It is used to process copper and aluminum parent lines of various specifications. As long as the corresponding processing unit Processing and high production efficiency. So, what are the characteristics of the bus machining machine? Let me briefly introduce it for everyone.

The bus processing machine equipment manufacturer Our company's professional production portfolio punch, CNC bus, the homeline processing machine equipment is beautiful and low. Welcome to inquire about the price of the parent line processing machine equipment.

Pay attention to the various original materials and repair materials of the device: Remember to remember the various original materials and repair materials provided by the supplier before reaching an agreement with the homeline processing machine manufacturer, and after Learning and understanding can have a certain understanding of the talents and planning of the factory. If you ignore the operations in this area, many unnecessary costs will occur after the equipment is put into production. The above is the more important aspects of the selection of the bus processor. We can pay attention to when selecting the homeline processor. What does the buser do?

The fat decoration device is fully injected from the fat -lip -up device until the old lubricating fat is discharged. After adding fat, running in running, excess fat fat will be discharged from the straight rail. After removing the lubricating fat, it will start to run. The amount of injection of the lubricating fat is about 1/3 to 1/2 of the space volume of the internal space of the linear guide rail. Lost factor.

0 notes

Text

Injection Molding Design Guidelines

1. Introduction

Injection molding is a widely used manufacturing process for producing plastic parts with high precision and efficiency. To ensure successful and cost-effective production, it is crucial to follow proper design guidelines for injection molding. In this blog, we will explore the key considerations and guidelines that designers should keep in mind when designing parts for injection molding.

2. Understanding Injection Molding Process

A. Overview of Injection Molding

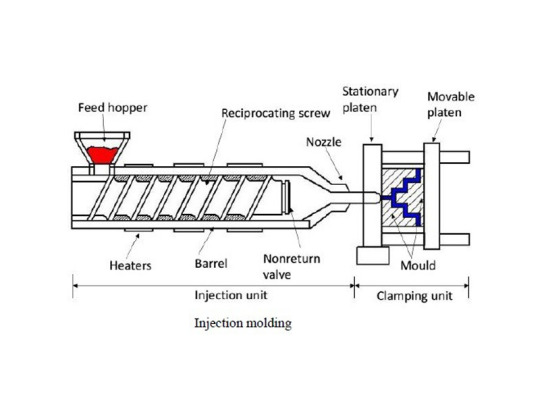

Injection molding is a widely used manufacturing method due to its versatility, speed, and accuracy. It can produce complex geometries and intricate details with minimal material waste. The process is suitable for a broad range of materials, including thermoplastics, thermosets, and even some metals.

B. Key Components of Injection Molding Machine

An injection molding machine comprises several key components, such as the clamp unit, injection unit, control system, and heating and cooling systems. The clamp unit holds the mold in place and applies pressure to keep it closed during the injection and cooling phases. The injection unit is responsible for melting the plastic and injecting it into the mold cavity.

C. Basic Steps in Injection Molding Process

The injection molding process typically involves several steps, including clamping, injection, cooling, ejection, and mold opening. These steps are repeated for each cycle, resulting in the production of a large number of identical parts.

3. Design Guidelines for Injection Molding

To ensure successful injection molding production, it is essential to follow certain design guidelines. These guidelines help optimize the part design for manufacturability, reduce defects, and improve overall production efficiency. Let's explore some key design guidelines for injection molding:

A. Wall Thickness: Maintaining uniform wall thickness is crucial to prevent warping, sink marks, and other defects. The recommended wall thickness range typically falls between 0.5mm and 3mm, depending on the material and part requirements. Avoiding thin and thick wall sections is important to ensure consistent cooling and reduce stress concentrations.

B. Draft Angle: Draft angles facilitate easier ejection of the molded part from the mold cavity. Typical draft angles range from 0.5° to 2��, and their application depends on factors like material type, wall thickness, and texture requirements. Considerations for draft angle placement include minimizing visible impact on part aesthetics and ensuring uniformity to avoid warping.

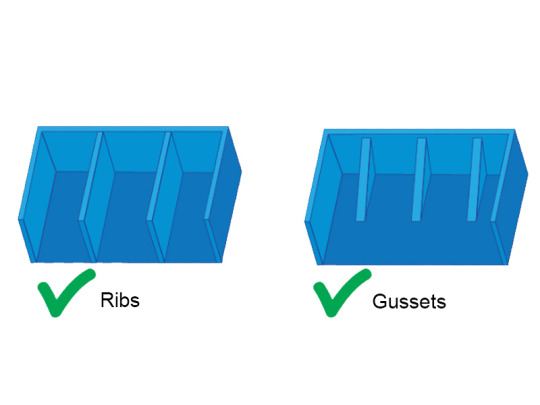

C. Ribs and Bosses: Ribs provide structural support without adding significant weight, while bosses are used to mount components or fastenings. Design guidelines for ribs include limiting their height, adding fillets to stress concentrations, and maintaining uniform wall thickness transition. Effective boss design considers factors like boss height, diameter, and location to ensure adequate strength and minimize material stress.

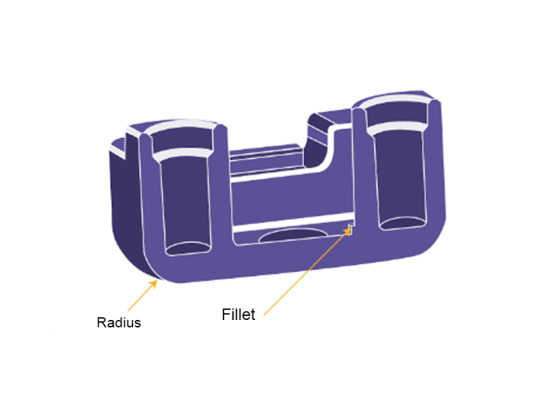

D. Fillets and Corner Radii: Fillets and corner radii help distribute stress evenly, reducing the likelihood of cracks or fractures. Recommended sizes for fillets and corner radii depend on the wall thickness and material properties. Benefits of radiused corners include improved strength, easier mold flow, and reduced stress concentrations.

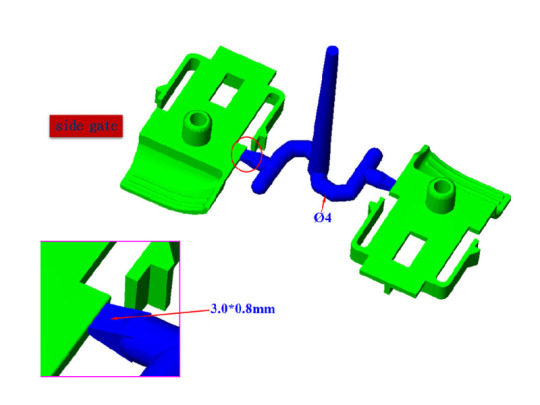

E. Gate Position: Proper gate position ensures efficient molten plastic flow into the mold cavity, minimizing turbulence and air entrapment. Gate locations should be strategically chosen to promote balanced filling, reduce sink marks, and minimize visible gate marks on the final part. Gate design considerations include gate type, size, and orientation relative to part features.

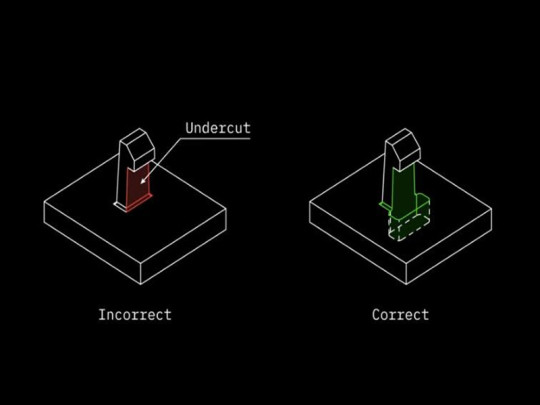

F. Undercuts and Side Actions: Undercuts are features that prevent the part from being ejected straight out of the mold. Design strategies for undercuts involve creating slides or lifters to allow for part removal. Side actions, such as cam mechanisms or旋转cores, can also be incorporated into the mold design to facilitate complex part geometries and undercuts.

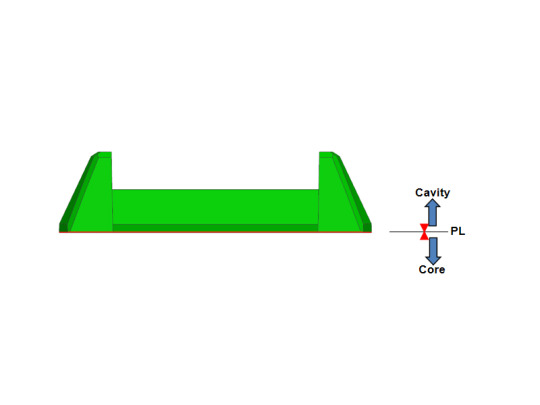

G. Parting Lines and Ejection: Parting lines are visible lines on the final product where the mold halves meet. Determining optimal parting lines requires considering factors like part aesthetics, functionality, and ease of mold assembly. Ejection methods, such as ejector pins or air ejection, should be carefully selected and positioned to avoid damage to the part during ejection.

4. Design for Manufacturability (DFM)

A. Collaborating with Molders and Toolmakers

Engage molders/toolmakers early in design process before tool production. Understand their capabilities and limitations to avoid issues down the road. Incorporate process and material experts' feedback into design revisions.

B. Prototyping and Testing

Rapidly test designs using 3D printing or machined prototypes. Evaluate fill patterns, strengths, dimensional stability with sample parts. Refine designs based on what's easy/difficult to mold. Simulate productions processes to catch issues early.

C. Iterative Design Process

DFM involves continual evaluation and optimization. Make small, incremental changes verified through prototyping. Multiple design-test cycles lead to robust, manufacturable parts. Collaborate cross-functionally to resolve problems at design stage.

D. Design Validation and Optimization

Establish tolerance standards and test plans for validation. Conduct final molding trials with production intent materials. Collect process data and finished part metrics. Quantitatively measure how designs meet engineering targets. Further enhance designs based on test results and production experience.

5. Conclusion

Designing parts for injection molding requires careful consideration of various factors to ensure successful production and high-quality end products. By following the design guidelines outlined in this blog, designers can optimize their designs for the injection molding process, minimize manufacturing issues, and achieve cost-effective production. Collaboration with experienced injection mold maker and Alpine mold, along with proper prototyping and testing, will further enhance the design process and lead to improved manufacturability. Remember, a well-designed part is the foundation for a successful injection molding process.

1 note

·

View note

Photo

Min-Hui C-Type injection molding machine can match the characteristics of the embedded parts and the molding requirements, and match the skateboard type or the turntable type to increase productivity and improve efficiency.

#C-Type injection molding machine#plastic injection molding#vertical injection molding machine#injection molding machine#injection molding machine manufacturer#minhui machinery#vertical plastic injection machine#Min-Hui

0 notes

Text

Mica Band Heaters vs. Ceramic Band Heaters: Which One is Right for You?

When it comes to industrial heating solutions, two popular options often come up: Mica Band Heaters and Ceramic Band Heaters. Both are widely used in applications like plastic injection molding, extrusion machines, and other manufacturing processes. But how do you know which one is right for your needs? In this article, we'll explore the key differences, advantages, and best-use scenarios for each heater type.

Understanding Mica Band Heaters

Mica Band Heaters are constructed with thin sheets of mica insulation that encase a resistance wire. The assembly is then covered with a metallic outer sheath, usually made of stainless steel. Mica, known for its excellent thermal conductivity and electrical insulation, allows these heaters to provide quick and efficient heat transfer.

Key Features of Mica Band Heaters:

High Thermal Conductivity: Mica's natural properties allow for quick and even heat distribution.

Compact Design: Their slim design makes them perfect for applications where space is limited.

Cost-Effective: Mica Band Heaters are generally more affordable compared to other industrial heaters.

Fast Heat-Up Time: They reach the desired temperature quickly, minimizing energy consumption.

Maximum Temperatures: They are typically effective up to 900°F (482°C).

Ideal Applications:

Plastic Injection Molding

Extrusion Machines

Packaging Equipment

Food Processing Machinery

Understanding Ceramic Band Heaters

Ceramic Band Heaters, on the other hand, are built differently. They feature ceramic insulation bricks that surround a resistance wire, all encased in a metal sheath. This construction allows for more efficient heat retention and even distribution across the surface.

Key Features of Ceramic Band Heaters:

Superior Heat Retention: The ceramic bricks act as insulators, maintaining heat longer and reducing energy consumption.

High Temperature Capacity: These heaters can handle temperatures up to 1200°F (649°C), making them suitable for high-temperature applications.

Durability: The ceramic build is robust and long-lasting.

Energy Efficient: Their design minimizes heat loss, leading to lower energy costs.

Wider Heating Coverage: Ceramic Band Heaters tend to distribute heat more evenly over larger areas.

Ideal Applications:

High-Temperature Plastic Processing

Blown Film Extrusion

Pipe Extrusion

Drum Heating

Mica vs. Ceramic: A Side-by-Side Comparison

CriteriaMica Band HeatersCeramic Band HeatersHeat-Up TimeFastModerateMaximum Temperature900°F (482°C)1200°F (649°C)Energy EfficiencyModerateHighDurabilityGoodExcellentCostMore AffordableSlightly ExpensiveHeat RetentionModerateExcellent

Which One Should You Choose?